Our Technology

Manufactured by IPAM Group, the OXYION ™ technology is an applied engineering solution focused on air purification and surface sanitation. Developed more than 25 years ago by professional experts in the field of biotechnology, it is a unique and harmless solution for people’s health.

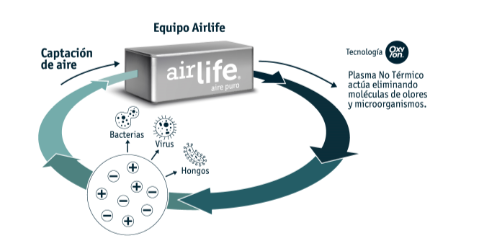

It consists of a Modulated Dielectric Barrier Discharge (MDBD) device, composed of HFM & SRM (High Frequency Module & Sequential Regulation Module) units connected to a reaction chamber with a set of open electrodes, which is specially designed to produce modulated electrical pulse discharges at two different frequencies. This electrical discharge generates a type of Non Thermal Plasma (NTP) composed of water vapor, oxygen, hydrogen, reactive nitrogen and molecules including peroxides, hydroxyl radicals, as well as trace-level ozone. This NTP forms a set of atoms and molecules with synergistic effect for the neutralization, destruction and active elimination of microorganisms present in the air and surfaces. For this purpose, applied engineering associated to each case has been developed, which allows applications in a safe, clean and highly efficient way.

In this way, a wide variety of organic and microbiological contaminants are controlled, increasing the biosafety of the air we breathe inside cars, work areas, offices, restaurants, clinics, hotels and public spaces. With Airlife, environments are left free of up to 99.99% of viruses, bacteria, mold and unpleasant odors, protecting the health of people in their daily activities.

The Oxyion technology has been validated and/or certified in results, design and manufacturing by more than 40 international studies, among them: Microbiological studies performed by Food Safety & Process Technology (USA), Cesmec (Chile), Ainia (Spain), Intertek (Intl.), and the European Community CE Certification, (Spain), thus complying with all worldwide safety standards.

Effect of Oxyion Technology® to create a safe environment for the control of human Coronavirus on various inoculated surfaces.

Effect of a Reactive Oxygen Species – Generating System for Control of Airborne Microorganisms in a Meat – Processing Environment.

Evaluation of the Efficacy of ROS reactor at Reducing Populations of Methicillin Resistant Staphylococcus aureus, Listeria Monocytogenes and Acinetobacter baumannii on Stainless Steel Surfaces.

Evaluation of the application of Oxyion technology to reduce contamination in industrial surfaces.

Neutralization of Escherichia coli, Listeria and Salmonella in cooling coils, cardboard, wood, stainless, steel and plastic.

Inactivation of Enterococcus faecium on Whole Walnuts by Atmospheric Cold Plasma.

Evaluation of activated oxygen system to control botrytis and decay in perishables.

Evaluation of Oxyion Technology for aspergillus environmental fungus reduction.

Prediction of the sanitization periodicity of a vehicle’s air conditioning and cabin circuit using Oxyion/ Airlife system.

Response Surface modeling for the inactivation of Listeria monocytogenes on stainless Steel surfaces by Oxyion treatment

Evaluation of reaction chamber and reactive species for reducing microbial population son stainless steel, plastic and polyethylene surfaces.

Study of the effect of the sanitization of Oxyion Technology on the development of environmental mold inside a vehicle.

Oxyion Technology creating a safe food environment in the elimination of Infulenza A, mRSA Norovirus and Rhinovirus on various inoculated surfaces.

Microbiological Report on air and surfaces in Oxyion Airlife – treated vehicles. (Nº 084-B/09).

Registration in the United States Environmental Agency (EPA Est.N°: 090193-CHL-001).